The Software Beneath the Seats: How Bespoke ACIT Solutions Keep Flight Interiors Flying

Bespoke software solutions might sound like a prohibitively expensive investment, but having the right tools tailored and baked into your business processes can boost your bottom line. Over the past decade we’ve partnered with Flight Interiors to develop an ERP (Enterprise Resource Planning) system that has become the backbone of their manufacturing business. The result? Streamlined processes, improved efficiency, and a powerful foundation for growth.

Flight Interiors are proudly local manufacturers of high quality aircraft interiors and responsible for manufacturing and maintaining the soft trim (think cushioning, carpets and seat covers) in every Air New Zealand plane. Delivering to aviation standards is a complex process – each component is meticulously tracked from commissioning to end of life, and knowing when it is at the end of its life is a critical part of the process. Flight Interiors can tell you just how safe your seat is, from when it was made until the day it is replaced.

Understanding just how much goes into the manufacturing and maintenance process is incredibly interesting. Each component requires full traceability through a barcoded system. One manufactured part consists of all build-up material information including costs and labour, flammability records and certification forms. From the thread, to the fasteners, to the fabric, every part is tested, and logged. It doesn’t end there, every seat cover is subject to a scheduled maintenance program controlled by Flight Interiors. When it’s dirty it’s not just cleaned, but as part of the precisely scheduled maintenance program it re-enters a system of checks and tests at Flight Interiors to ensure the integrity, quality and safety of the part. Then it’s re-dispatched in time to meet the complex flight schedules. That’s a lot of moving parts!

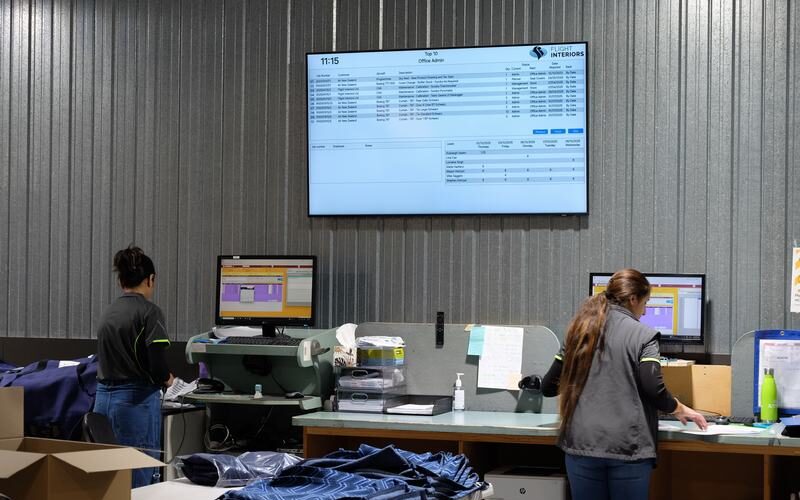

Our ACIT team, lead by Andrew Allen with a collaborative system design, have created an ERP software system that sits around that process, providing a complete picture of every item Flight Interiors produce. But it’s not just the production, it logs the required quality assurance and compliance notes required at an aviation industry standard, measures staff resource use, and costs on that item, as well as the levels above, to integrate workload balancing, track stock levels and batch details for individual stock items, as well as financials across every aspect of operations for a holistic overview. It’s resource planning meets business planning, saving untold time, reducing waste and downtime, and ensuring Flight Interiors hit all their critical metrics, and timelines.

The comprehensive nature of the system ACIT have developed with Flight Interiors is incredible, providing the depth of business insights that most companies dream of, all developed to integrate the complexities of manufacturing within the rigorous demands of the aviation industry.

Andrew at ACIT admits the Flight Interiors system has become a bit of a personal passion project, partnering with Russell Holdem at Flight Interiors and his team, to create a system that integrates with every aspect of the business. But he also says we demonstrate just how much efficiency can be engineered into a process with the right software solutions.

If you’d like to take the controls of your business, talk to the ACIT team about software tools to build in more efficiency.